Recommended

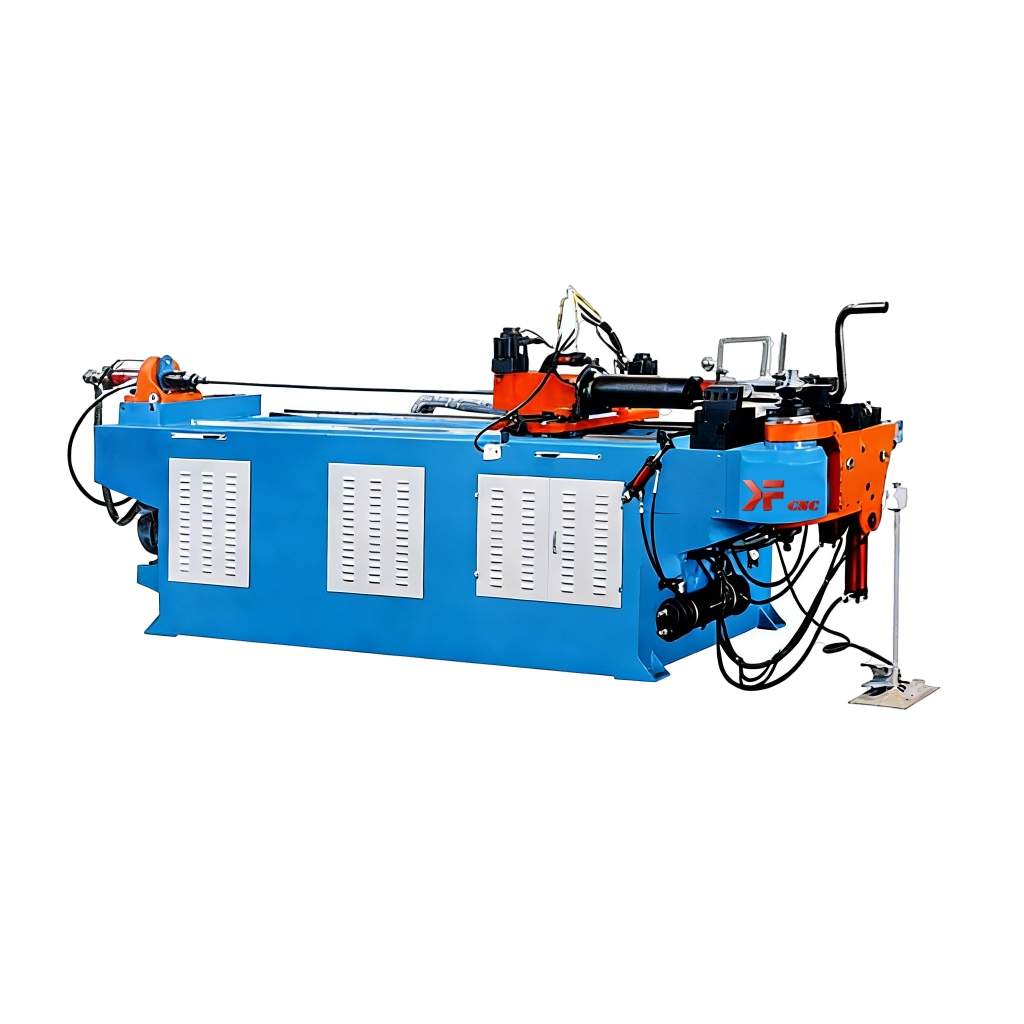

Products

Panel Bender

- Multilateral automatic continuous bending.

-Automatic programming software can finish all the process

- Automatically check and optimize. the process -All servo motor control, fast and energy saving

- Automatically control pressing force.

-Automatic programming software can finish all the process

- Automatically check and optimize. the process -All servo motor control, fast and energy saving

- Automatically control pressing force.

About Us

Jinan Kafe CNC Co.,Ltd. is a professional company set up by China Metal-forming Industry experts and industry veteran persons with integrated technology research, development, production and sales. The company is located in Jinan Economic Development Zone in China. Up to now, Kafe has achieved many patents including National High-tech Enterprise Certification, ISO9001 Quality Management System Certification, CE Certification, and Intellectual Property Management System Certification.